America POD centrifugal extractor

America POD centrifugal extractor

POD centrifugal extractor is a kind of unique separation and extraction system, small body, the use of centrifugal force to improve the acceleration, usually used in extraction, separation, reaction, chemical washing and other processes. Two phase separation is produced by the effect of external pressure and time, so the acceleration force allows you to spend less time to obtain greater production benefits.

POD centrifugal extractor in liquid/liquid processing applications can increase the gravity of more than 3000 times, to separate specific gravity different phase. The productivity benefits of such gravity augmentation systems are much greater than those of single-gravity systems such as gravity towers.

American POD centrifugal extraction function separation density difference as low as 0.01 of the material.

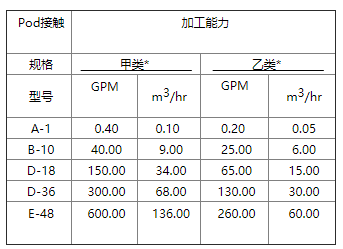

POD centrifuge extractors are available in five standard models, with processing capacities ranging from 1.51 liters per minute in laboratory trials to 2271 liters per minute in production applications.

* Application criteria

Class A - multi-stage extraction or washing, non-mixable liquid phase gravity ratio is usually 0.06 to 0.15.

Type B - fermentation liquid extraction, gravity difference is similar (but this liquid is usually emulsion).

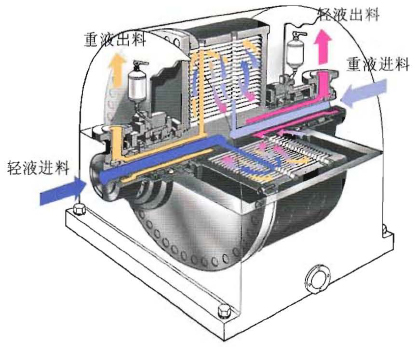

The working principle of POD centrifugal extractor is as follows (see figure above) :

The rotor is equipped with coaxial hoops with holes. When the rotor rotates, heavy liquid (HL feed) droplets pass through the light liquid phase area, converge on the outside of the hoop, and then pass through the hoop hole and gather at the outlet near the top of the POD contact machine (HL discharge). Light liquid (LL feed) droplets converge on the inner side of the hoop through the shaft, and then gather through the hoop hole at the outlet near the shaft (LL discharge).